About Us

Plant for Fuel Pump Module

25000 square meters

OEM supplier,

20 years production experiences

industry leading manufacturer with leading tecnology

adavanced highly automatic production

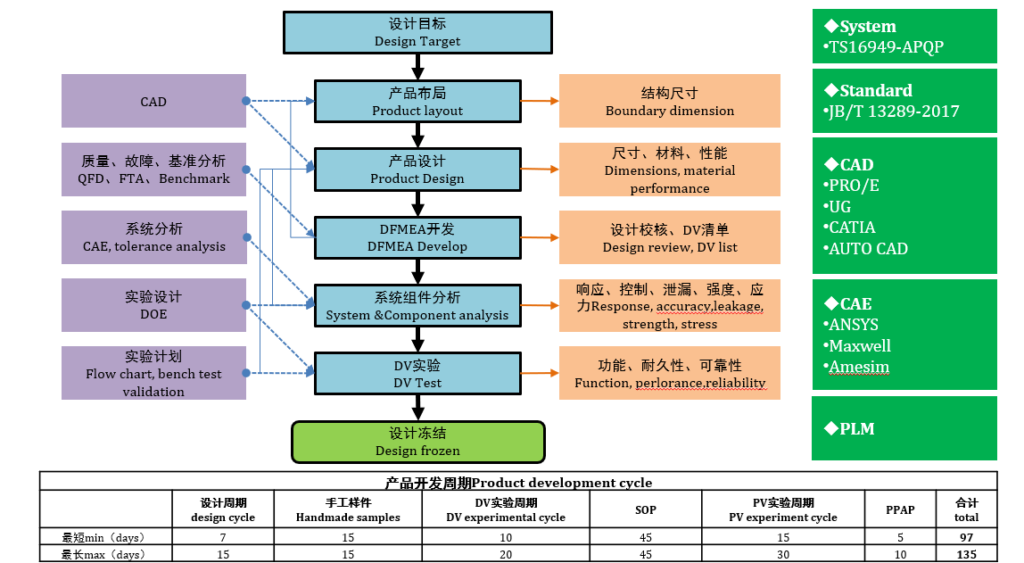

Innovation-driven Solutions

follows the concept that “quality by design” to develop new products. The team has 16 years experience in fuel pump assembly R&D. From tooling design to product design and fixture design, UG and ProE three-dimensional software are used . five tools of quality management system (APQP, FMEA, PPAP, SPC, MSA) are applied to optimize the design to achieve product quality optimization (Error & Mistake Proofing)

exports products to Europe, the Americas, the Middle East, Southeast Asia, and other regions. This international presence is a testament to the company’s commitment to delivering high-quality products that meet the diverse needs of customers worldwide.

extends a warm invitation to interested parties to visit their factory or contact them directly for more information. With their dedication to innovation, quality, and customer satisfaction, the company is poised to continue its success in the automotive and motorcycle industry.

Endurance testing ,high and low temperature testing,leakage,flange tightness testing..etc more than 30 types experiments will be performed to ensure complete customer satisfaction

Plant for VVT & OCV

47000 Square meters ,

supplying to world top brands .high and stablt quality guaranteed.

excellent team ,70% engineers are from Oe manufacturer, The production process and testing items are all benchmarked against the OEM and strictly implemented;

Before new products are produced in small batches: a series of extreme experiments such as loading and road tests, high and low speeds, sudden acceleration and deceleration, and mountain climbing; vibration experiments, dirty oil experiments, high and low temperature experiments, etc. The durability test of each model is no less than 500 hours of testing;

Key processes, all produced in-house to ensure dimensional accuracy; Key dimensions: 100% tested and traceable

Raw Materiales

new and high quality raw materiales from korea,japan,taiwan etc…for plastic injection ,

Strict Quality Control

strictly perform according to IATF16949 ,we are always the pioneer for new and innotive tecnology for improving quality .various tests are performed before ,between and after production .

In Process Quality Control :all parts will be tested separatedly according to operation guidance 。100% test each item

Automatic Production lines with leading tecnology

95% automatic production lines ,many self designed production lines cater to maintain stable and high quality performance . 92% spare parts for our products are manufactured in house, automatic assembly lines with automatic testing each one by one .

Experiment tests

experiment test examples

1.Endurance testing In-house

2.High and low temperature testing In-house

3 .Fuel compatibility testingIn-house

4.Hot fuel handling testing In-house

5.Temperature explosureIn-house

6.Float cycling In-house

7.High pressure air tightness In-house

8.Vibration test In-house

9.Noise test In-house

10.Salt spary test In-house

11.Insulation test In-house

12.Leakage test for fuel pump module In-house

13.Electromagnetic compatibility test In-house

Varivable valve timing(VVT) plant

supplying for world top brands ,stable and high quality ,strictly follow the OEM production process

VVT develop capability

CAPABLE OF OE DESIGN AND MANUFACTURING

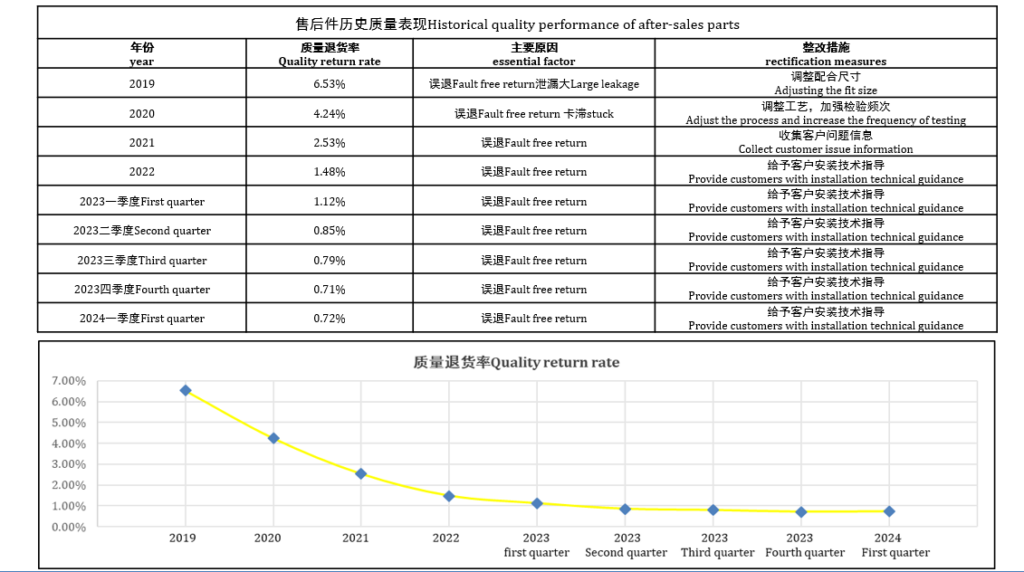

Historical quality performance of after-sales parts

Schedule a Visit

Our Team

Mr.Yong

Founder – CEO

Ms.TINA CHEN

Sales Manager

Mr.Gaotingchao

Chief Engineer

Mr.wang jianwei

QA

Mr.xu

Tecnician Head

Mr.liu

Production head